10 minutes09/02/2021

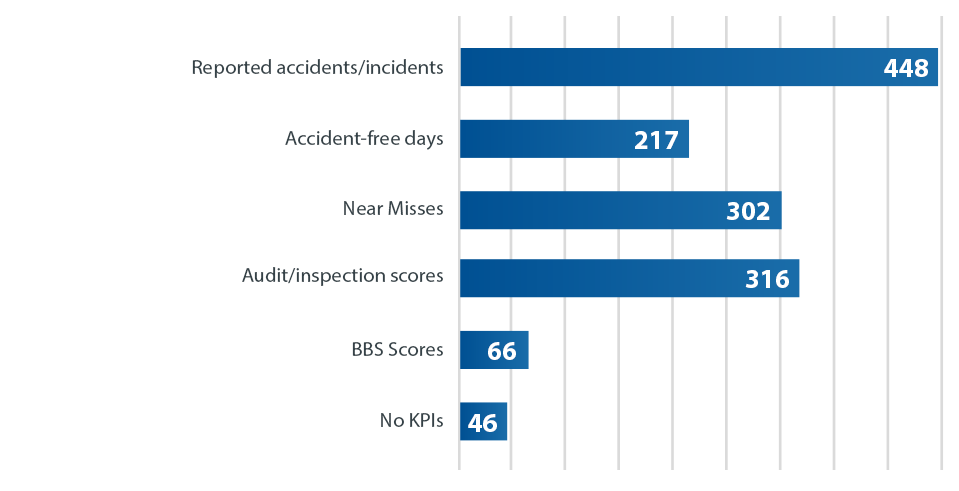

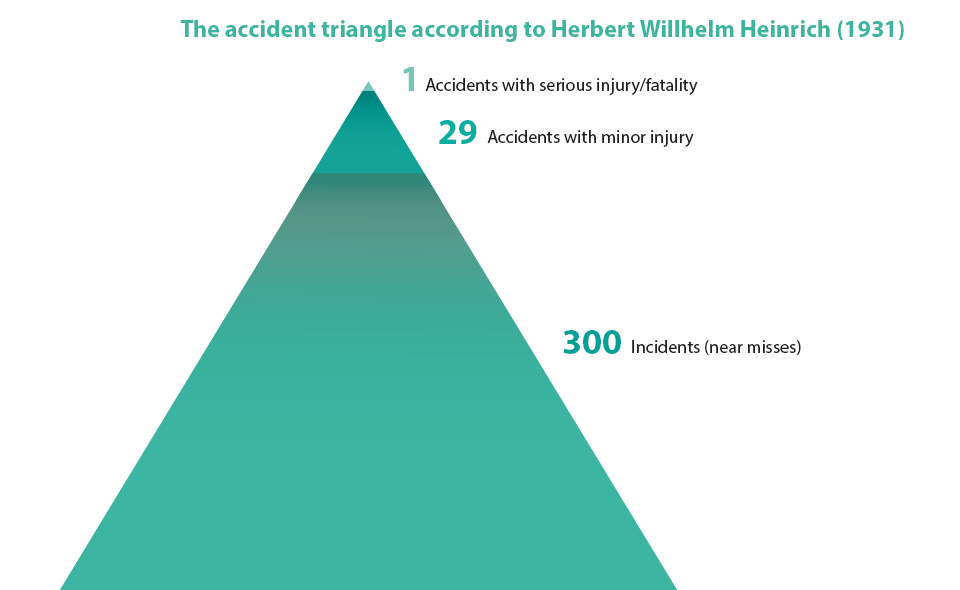

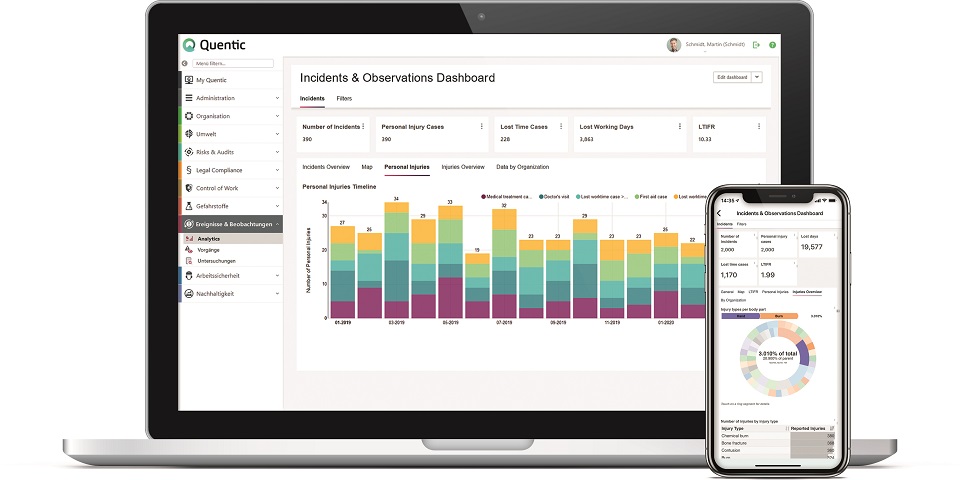

Are you looking to make continuous improvements to the health and safety of your company? If so, it is important to figure out where you currently stand, define your goals and identify potential improvements. Key performance indicators (KPIs) play an important role in this process, as they make it possible to draw comparisons and place them in the context of measures you have put in place. This in turn enables you to find the weaknesses in your company’s existing occupational safety processes and also to communicate your successes. In this article, we will outline the most commonly used KPIs and discuss the aspects you should consider when selecting relevant metrics for your company.