7 minutes06/23/2023

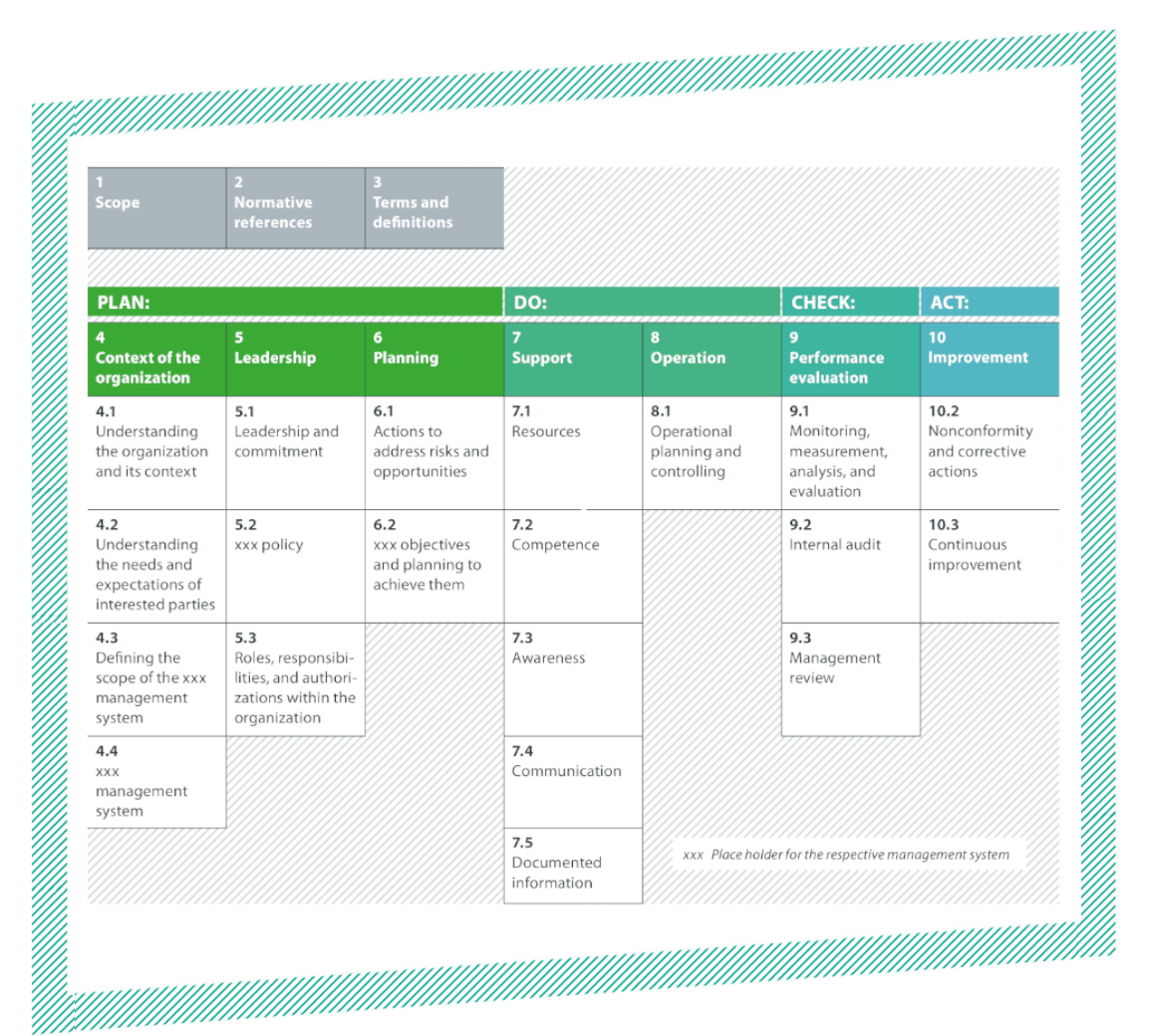

Since its inception in 1987, with the introduction of the first management system standard ISO 9001, the field of management systems has undergone a significant evolution. Initially focused on quality, environmental, and occupational health and safety management until the early 2000s, the landscape changed in 2005 with the inclusion of many new systems. At the same time, the range of management expectations has steadily expanded, requiring compliance from organizations of all sizes and across geographic boundaries.

In response to the pressing challenges of our time, organizations are increasingly implementing a wide range of management systems that go beyond ISO 9001, 14001, 45001, and 50001 - the traditional four major EHSQ management systems. As the number of management systems increases, managing their requirements separately or in parallel becomes increasingly challenging. The growing complexity of their requirements makes it impractical to manage them individually. Operating multiple systems in isolation leads to duplicated documentation efforts, increased regulatory risk, and decreased employee and stakeholder buy-in. This inefficiency underscores the need for a different approach—an integrated one that can effectively address the wide range of requirements.