An energy management system in line with ISO 50001

6 minutes 04/26/2022

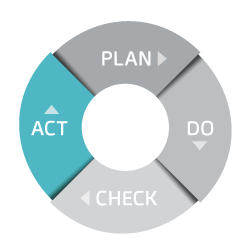

Effective use of resources is an increasingly high-profile issue. The Paris Agreement and the goal of limiting global warming to below 2°C has drawn an enormous amount of attention to the issue in recent years. Achieving this target means a radical reduction in greenhouse gas emissions as well as the decarbonization of value chains. Therefore, companies are faced with the challenge of securing and using cost-effective yet sustainable energy supplies. Active energy management has a decisive role to play in this. The international standard for energy management systems ISO 50001 is a globally recognized and certifiable standard for introducing and maintaining an energy management system. It can be used by organizations of all types and sizes. The objective of an energy management system is to continuously optimize an organization’s energy performance. This is achieved by measuring, monitoring, and controlling energy-consuming processes and systems. The measures derived from these actions help companies make targeted improvements in energy performance. To facilitate this, company management has to provide the necessary resources, define responsibilities, and document processes accordingly. This ensures that companies adopt a forward-looking approach to energy topics and associated legal requirements. It also enables them to generate motivation among their employees and cut their operating costs.