9 minutes11/02/2022

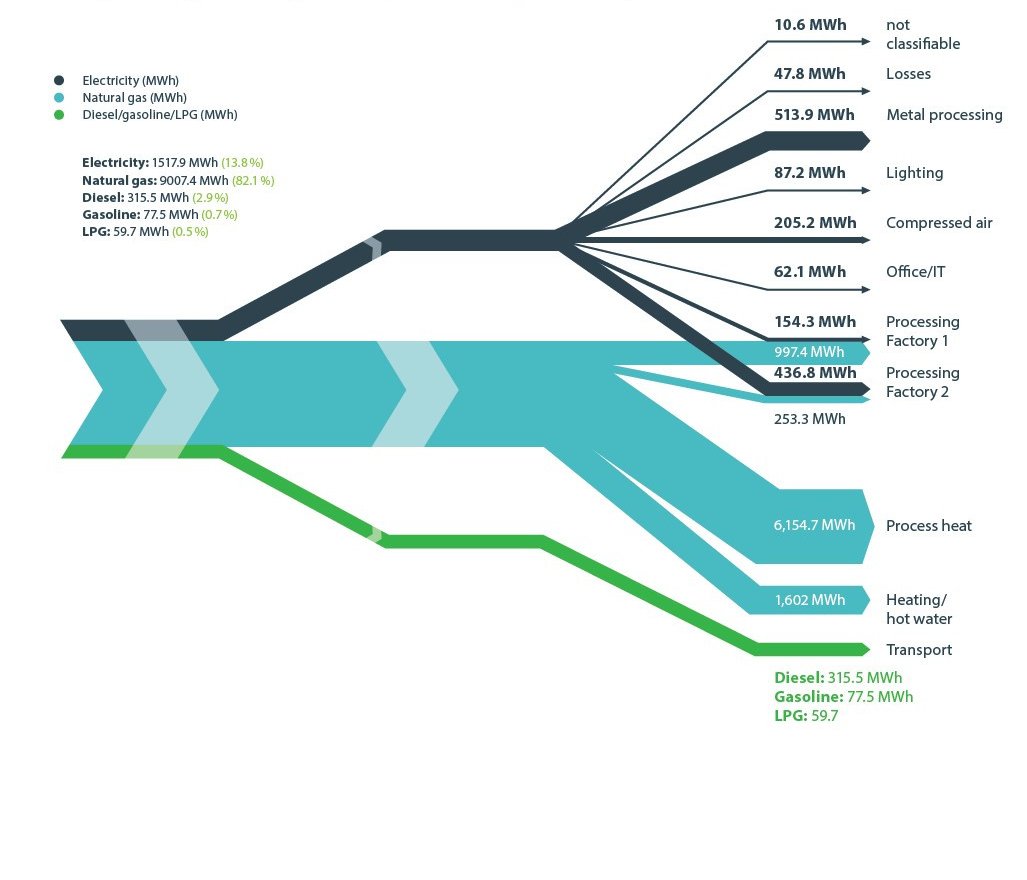

Identifying locations with high energy consumption is highly relevant for companies. In view of climate change and current political and social challenges, it is more important than ever to reduce the consumption of finite resources as much as possible.

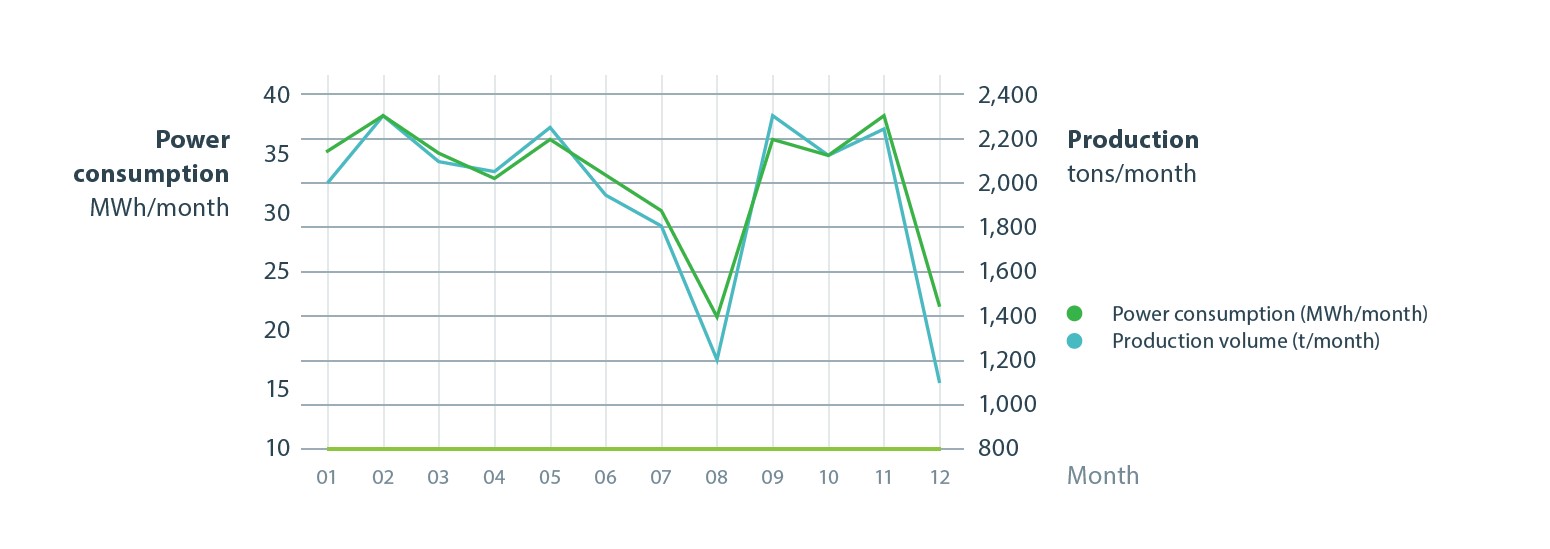

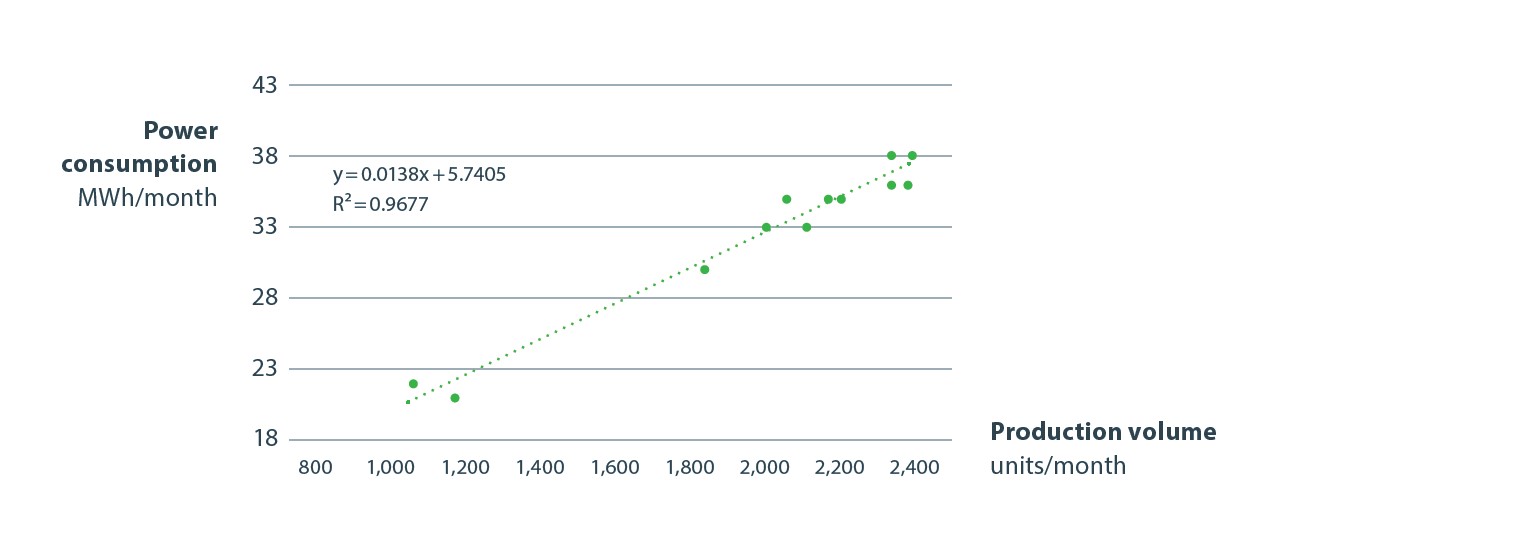

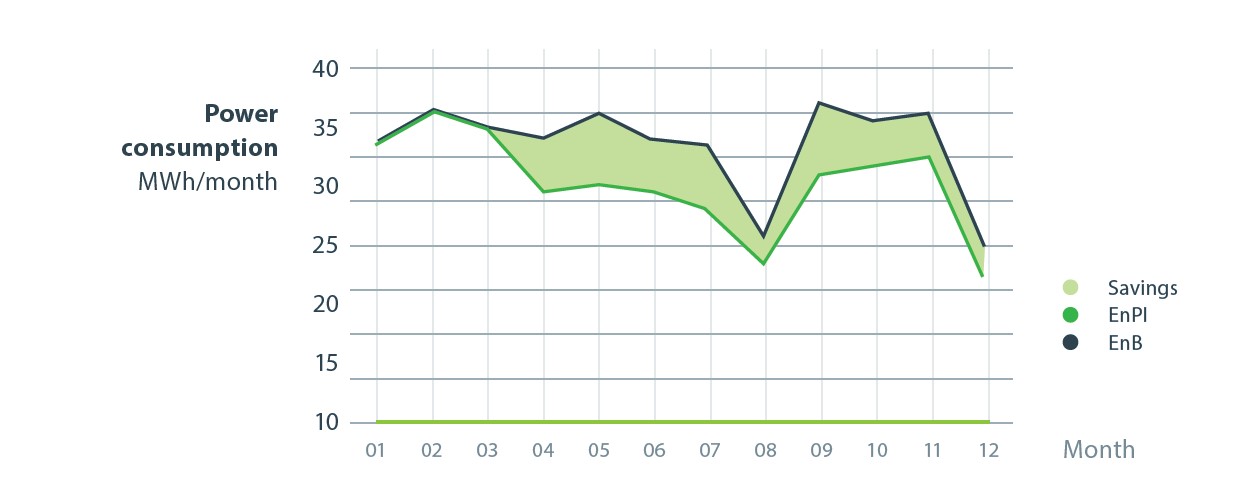

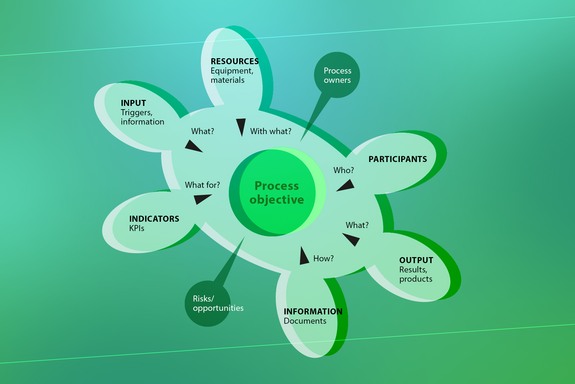

In order to proceed systematically and be successful in the long term, a suitable energy planning process is needed. This process starts with defining significant energy uses (SEUs). These are then assessed using energy performance indicators (EnPIs) and continuously monitored through energy monitoring. The action plan finally sets concrete targets for reducing consumption. ISO 50001, the international standard for energy management, provides clear guidance on the structure and implementation of an energy planning process as part of the Plan-Do-Check-Act cycle. In this article you will learn how to proceed and what you need to consider