6 minutes08/09/2022

by Stefan Ganzke

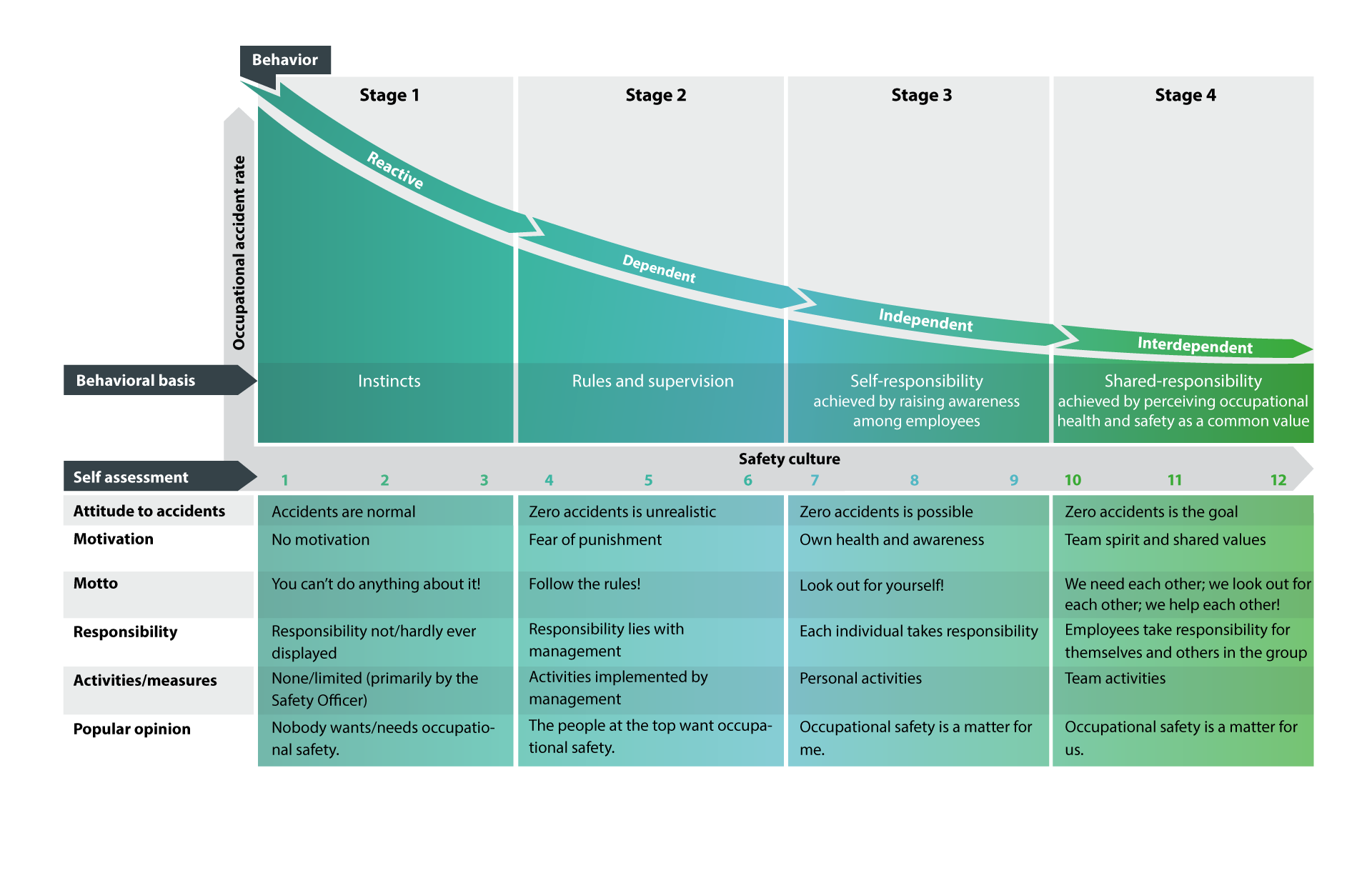

If the Lost time injury frequency rate (LTIFR) in your company is stagnating – i.e. if your reported workplace accident figures have plateaued – and you would like to improve your safety culture, you need to turn to new strategies and methods in addition to technical, organizational and personnel-related (TOP) safety measures. Improved occupational safety demands a stronger focus on the people in your company and how they behave.

Do you want to have a positive impact on occupational safety? If so, you need a basic understanding of behavioral analysis and how to change people’s behavior. To successfully transition to safe behaviors and thus achieve a sustained reduction in workplace accidents, your company’s safety culture needs a specific DNA. To describe this better, we’ve introduced the term “Safety Culture DNA”. It has three essential DNA strands:

- Safety mindset

- Communication

- Behavior-based safety

This article deals with the first DNA strand, Safety Mindset, and the importance of mindsets in relation to occupational safety. Learn about the role mindsets play in developing a safety culture as described by the Bradley Curve, how to foster a safety culture, and how you can influence and promote more conducive mindsets to occupational safety.