3 minutes01/02/2018

Written by Timo Kronlöf

When searching the web or asking colleagues for forms on things like incident reporting, vehicle checklists, inspection templates or safety checklists, you will find that what you usually get is a printable version of a PDF, a Word file or an Excel file. For young people it is alien for them to have to print and fill in a form, however, if you are in your mid-thirties or older, you’ll have practised printing and filling paper forms for decades. So there’s no need to change this, right? No, wrong!

The mobile revolution has not just brought the internet to everyone, but it has also connected hardware that lets us do reporting online without the need to print and scan or print and type. We can easily add pictures and assign tasks within our corporate environment without any interruptions.

The idea behind eliminating wasted tasks in reporting is not new, anyone from the quality field will think of the ‘Toyota Production System’ or the slightly newer ‘Lean Management’ where this is a central idea. We still see paper forms being used today for reporting in many places. In recent discussions with people mainly involved in safety reporting, I noticed that it is unclear where time is actually wasted. So, I decided to write a short Blog on what exactly it is you can eliminate.

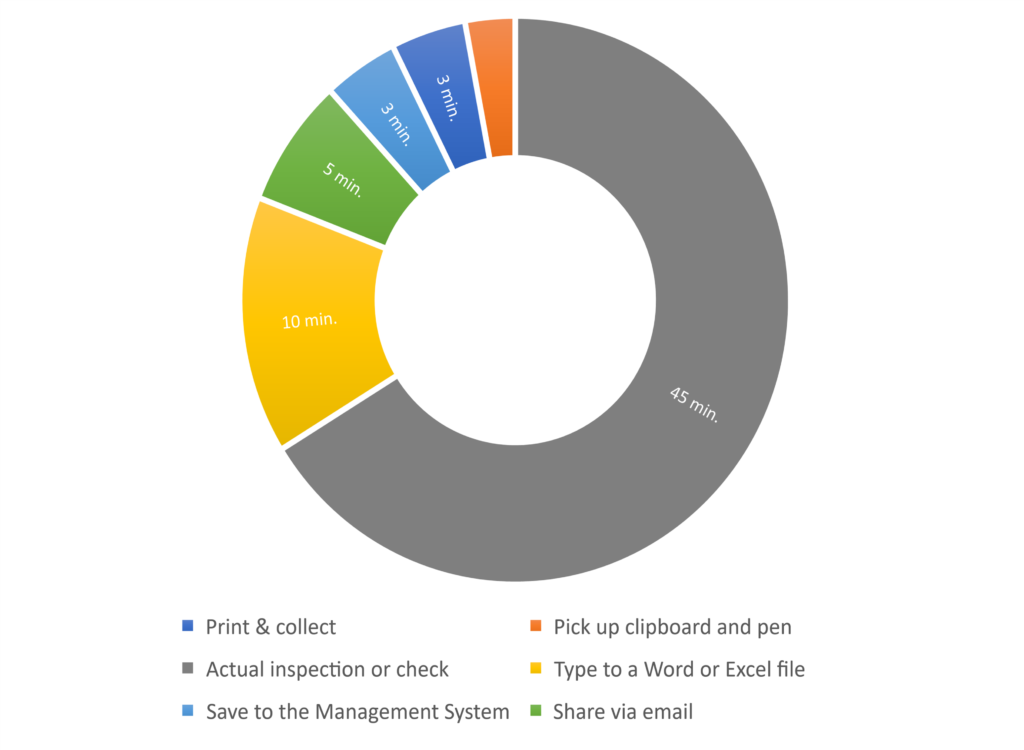

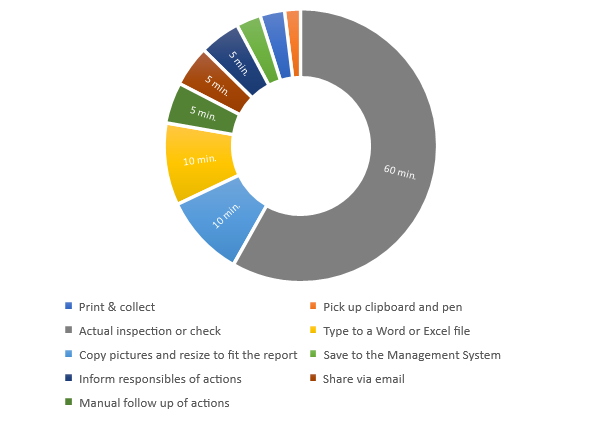

Imagine a case where a construction site walk should be done twice a day by the foreman at the end of their shift and the round takes 45 minutes to complete on average. What is the actual difference between a paper form and a mobile device?